About us

helio PLANET

About our work

help us to ADDaDOT™ by installing

transportable bio-waste reactors (HRUs) in your community to save our planet from harmful waste!

'another dot...another HRU...less waste'

about ...

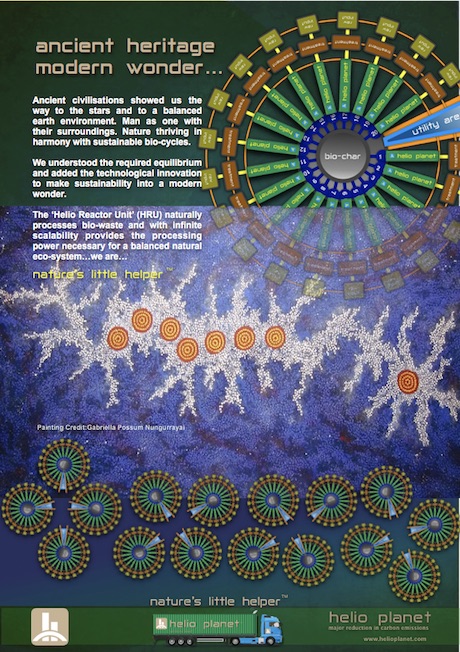

30 year heritage

The ‘Low Temperature Natural Extraction’ (LTNE) core technology is based on proven thermal engineering systems and patents that were initially created in late 1980's.

This core technology, was the basis of large, expensive thermal processing plants that were installed all over the world and operated by local government agencies to process waste streams from treated sewage plants, tanneries, abattoirs and many other wastes. These plants were very successful in converting waste to energy and to other desirous by-products. The main issues were that of plant size and high costs of construction. The issues were never about the technology.

Helio Planet has over the last five years created a 'Patent Candidate' technology that utilises the outstanding engineered core technology and produced a new 'Third Generation' range of unique, self contained, small footprint, transportable 'Low Temperature Natural Extraction' (LTNE) processing plants.

These transportable LTNE reactors are designed in Australia, manufactured in Germany and delivered globally as a turnkey operation to any corner of the planet where waste is an issue.

accredited engineering knowhow

The ‘Low Temperature Natural Extraction’ (LTNE) technology provides a new revolutionary product for the green waste, municipal solid waste (MSW), sludge and waste organics market. Unlike most other processes the technology offers significant resource recovery options.

The LTNE technology has considerable environmental and societal benefits over all ‘classic’ sludge and waste disposal alternatives (including recycling to agriculture, landfill and incineration) and generates ‘renewable’ energy and carbon sequestration credits thereby reducing emissions of greenhouse gases.

The key to the LTNE system is the molecular re-arrangement by heating, achieved by a biomass reactor process, plus intimate contacting of the product streams in the main conversion reactor to obtain the optimum quality of products. In this process, the sludge molecules are heated, to above 400°C (800°F), in an oxygen free environment (no combustion), and re-ordered into Bio-Gas, Bio-Char and Bio-Oil.

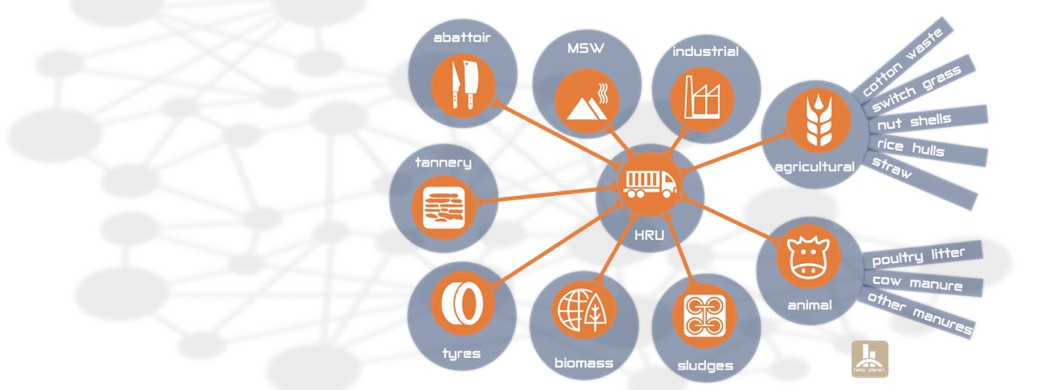

Many sources of organic matter can be used as feedstock for the LTNE reactor process. Suitable plant material includes: green waste, sawdust, waste wood, woody weeds; and agricultural sources including: nut shells, straw, cotton trash, rice hulls, switch grass; and poultry litter, dairy manure and potentially other manures. The LTNE reactor process is used as a form of thermal treatment to reduce waste volumes of domestic refuse. Some industrial by-products are also suitable feedstock including paper sludge and distillers grain.

One of the key strengths of the LTNE system is its ability to handle pollutants. With sludge containing a number of pollutants such as heavy metals, organochlorines, pathogens, toxins and/or Endocrine Disrupting Compounds (EDC’s). The majority of the heavy metals partition into the Bio-Char and, when this is combusted, the heavy metals become tightly bonded to the resulting ash. Unlike almost all other thermal processes, the heavy metals remain in the solid phase and are neither vapourised nor leachable. All organochlorines, toxins, pathogens and EDC’s are destroyed.

solutions based services

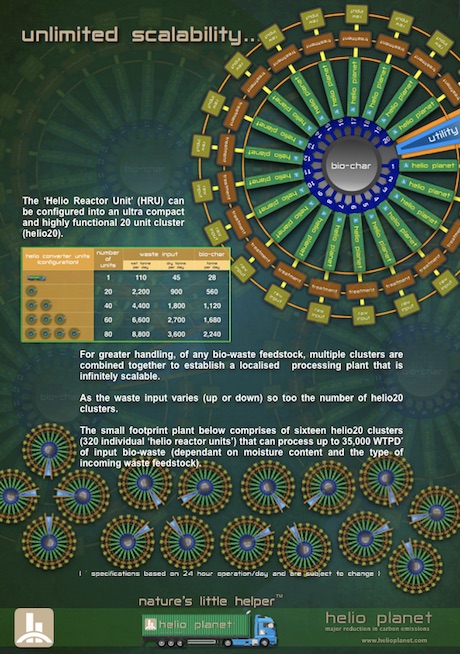

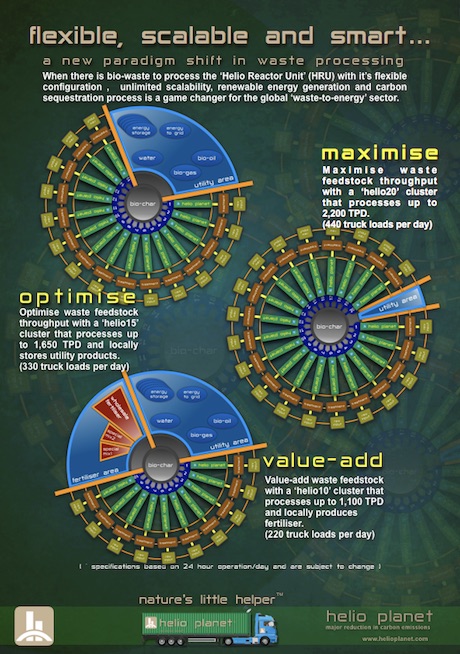

The Helio Reactor Units (HRU) are arranged into compact clusters to process large volumes of waste from local communities or cities.

These clusters form efficient waste processing plants capable of multi-volume waste handling. The essence of this configurable cluster is not only the input volume processing capability but its operational runtime efficiency.

Any maintenance issues are localised and dealt with quickly and easily. As maintenance issues are localised to each HRU unit the operational uptime of the entire cluster is kept at a maximum. In case of a catastrophic event in a single HRU it is simply totally replaced with a new unit without effecting the continued operation of the cluster. While the faulty unit is replaced the remaining units in the cluster are still performing to maximum capacity without effecting the input processing of the waste volume.

experienced executives

Our philosophy and methodology provides a community with the localised tools necessary to manage and process waste within their community rather than the traditional collect, transport and dispose process required in a centralised manner. These self contained, small footprint, transportable LTNE processing plants allow each community to manage and also benefit from the output. In this way large ultra-expensive centralised processing plants are avoided.

Collectively the Helio Planet engineers have over 120 years experience between them. Their passion to save the planet from waste streams has driven their creativity and have thus designed and delivered the LTNE processing plant technology. Their ingenuity is translated in the near-term 'Patent Candidate' submission.

Helio Planet's understanding and vast experience of this unique and proprietary technology will in future result in the creation of ‘Designer Energy Fuels’ (DEF) that are environmentally friendly, cost effective and cater for niche market requirements. These fuels will assist in the optimisation in engine development and in the direct reduction of environmental emissions.

viable economics

Our very simplistic business model is based on the eradication of global bio-waste to create valuable resources for sale.

The project economics are based on:

- a Helio Reactor Unit (HRU) is delivered to the waste site

- a tipping fee is paid by the waste owner to remove their waste

- water extracted from waste feedstock is given back to the community

- recovered resources are sold as raw commodities (bio-char, bio-oil)

- recovered raw resources may be refined as new products with higher economic benefit (fertiliser)

- recovered raw resources may be used as feedstock in turbines to create electricity (steam-fired-turbine)

We provide a community with the localised LTNE unit to process waste within their area rather than the traditional collect, transport and dispose process (landfill, sea-fill or incineration) required in a centralised manner. These self contained, small footprint, transportable LTNE processing units allow each community to manage and also benefit from the output. In this way large ultra-expensive centralised processing plants and landfills are avoided.

The third-generation Helio Planet LTNE technology is a commercially proven thermal transportable plant that provides a sustainable solution for the disposal of polluted organic sludges and other bio-wastes.

The transportable plant has application in the green waste, treated sewage and industrial sludge markets around the world. This is a very large market worldwide, estimated at over 30 million Dry Tonne Per Year (DTPY) in the developed world alone and growing at a rate of about 1 to 2 % per year.

An essential element of the business model is that revenue is generated at each step of the process that results in guaranteed outcomes for operators.

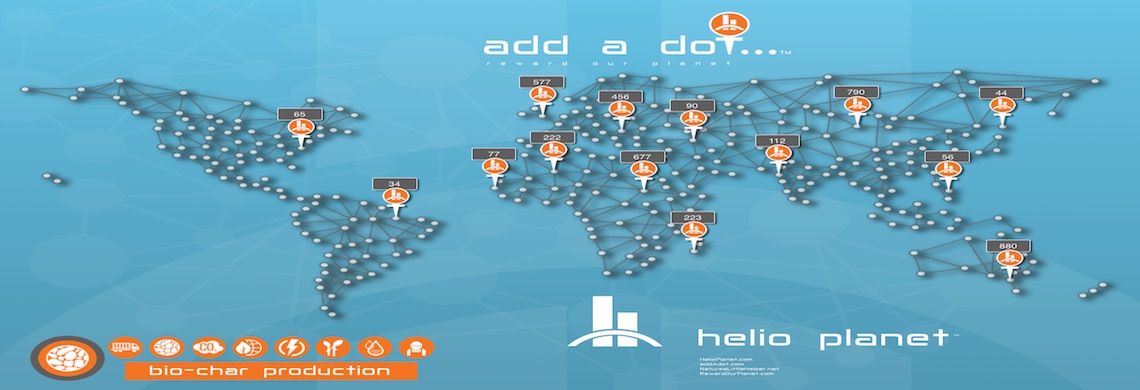

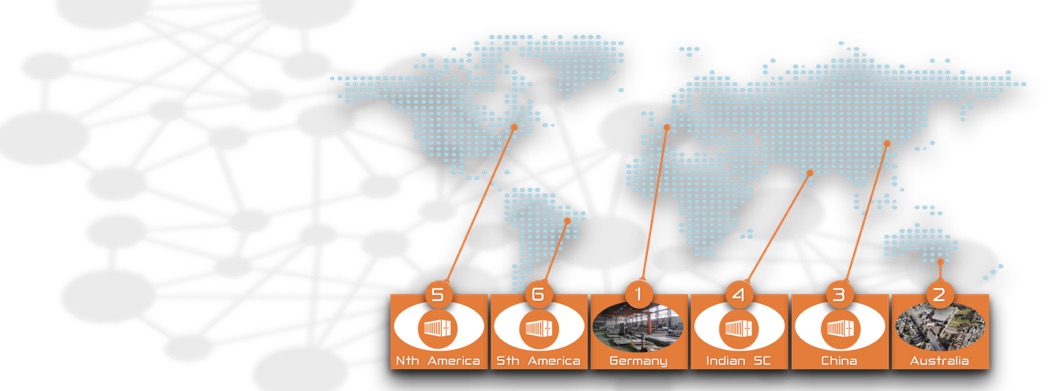

The global market is divided into four major segments:

- Zone 1 (EMEA = Europe, Middle East and Africa)

- Zone 2 (Asia and Australasia)

- Zone 3 (Americas)

- Zone 4 (Indian Sub-Continent)

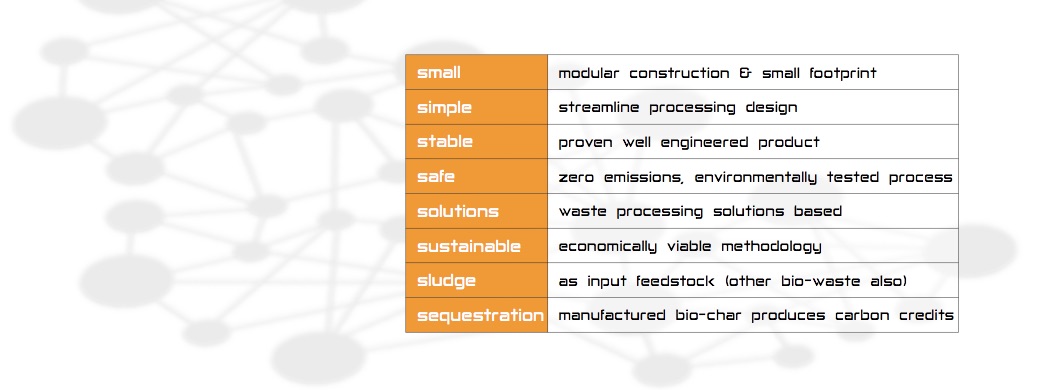

proven methods

Helio Planet's core technology is a 'third generation' derivative, spanning over 30 years of evolution, with new technological enhancements to process any bio-waste with ease and efficiency not seen before in waste processing equipment.

Helio Planet’s market differentials are based on unique product properties that competitors are unable to copy, replicate or source.

Helio Planet’s third-generation, transportable unit has heritage to the 1980’s issued pyrolytic patents.

The early successful efforts are linked to the many years of market leadership, R&D efforts, substantial financial support and patent protection that once dominated the global pyrolytic waste processing marketplace.

established manufacturing

The Helio Reactor Unit’s (HRU) will be manufactured in various global facilities in order to:

- maintain consistent quality levels

- high production output

- local material and employment

- to provide off-site district heating or thermal energy to industrial users

- to run electrical generators for the production of electricity

Each manufacturing facility will produce HCUs, under license, for its designated region.

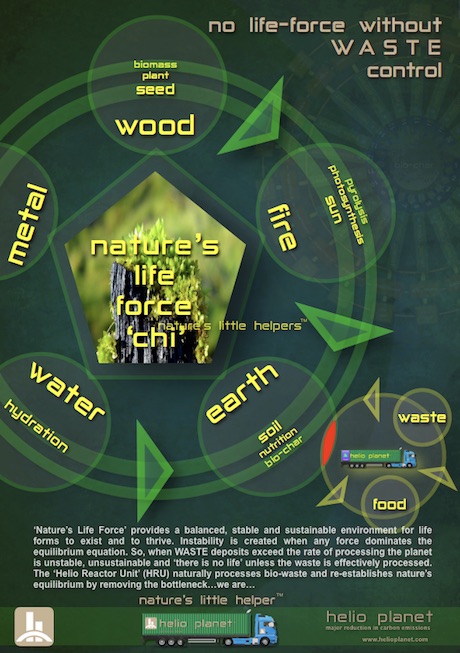

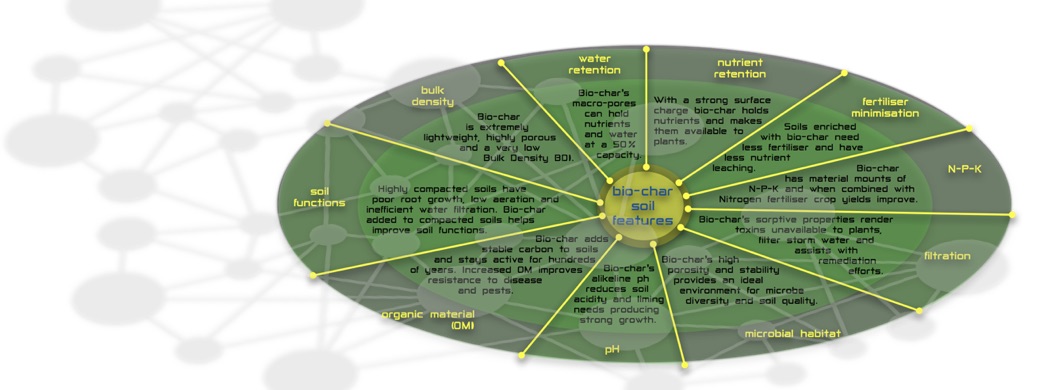

significant reductions in carbon emissions

The Helio Rector Unit (HRU) with 'Low Temperature Natural Extraction’ (LTNE) technology provides a new revolutionary product for the sludge, municipal solid waste and other waste organics market. Unlike most other processes the technology offers significant resource recovery options.

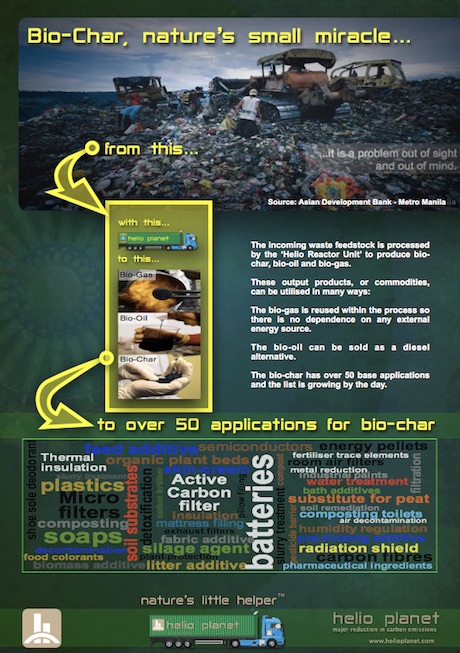

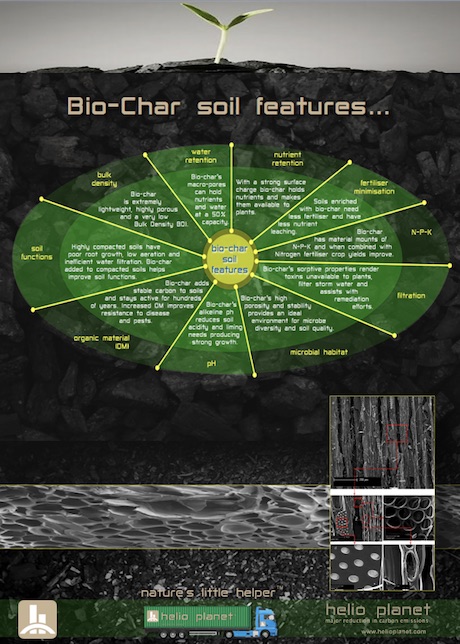

Bio-Char is one of the major resources produced by the HRU.

There is a global impact of bio-char on soil ‘Nitrogen Cycling’.

Bio-char is growing in acceptance as a ‘wonder-product’ within the farming and scientific communities. It’s unique porous structure has many beneficial advantages in rejuvenating soil and interaction with fertilisers. Bio-char’s unique structure has many advantages within the agricultural sector.

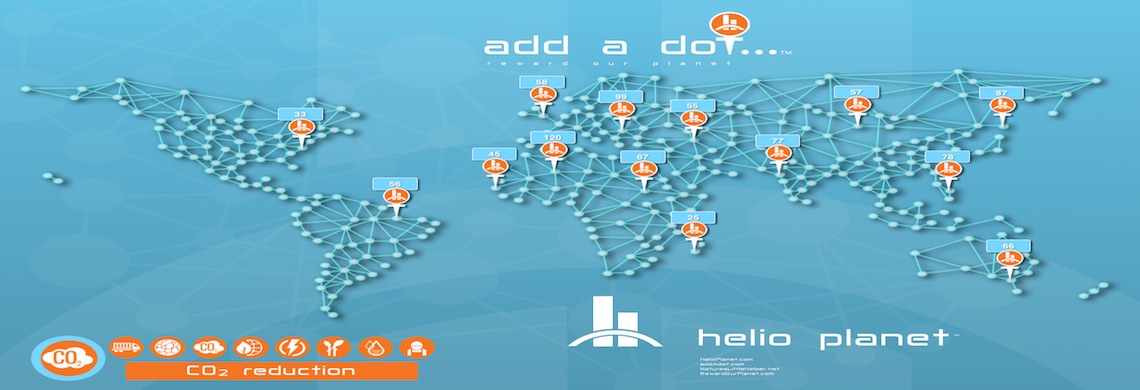

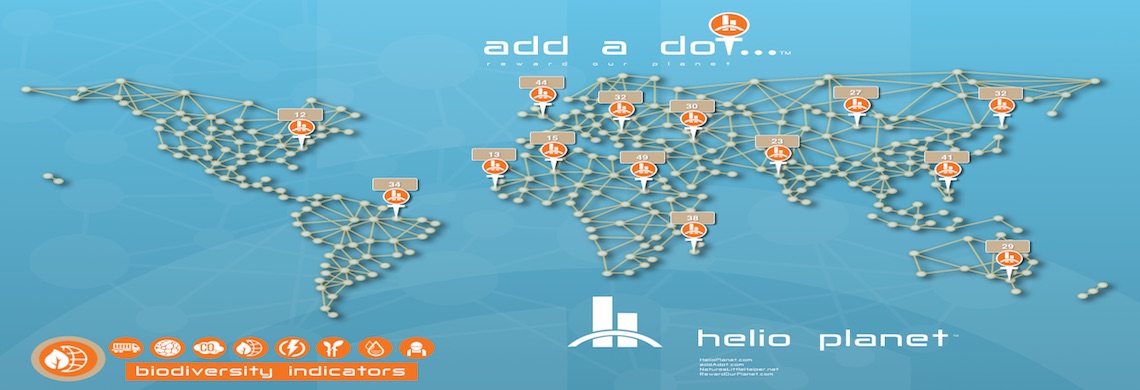

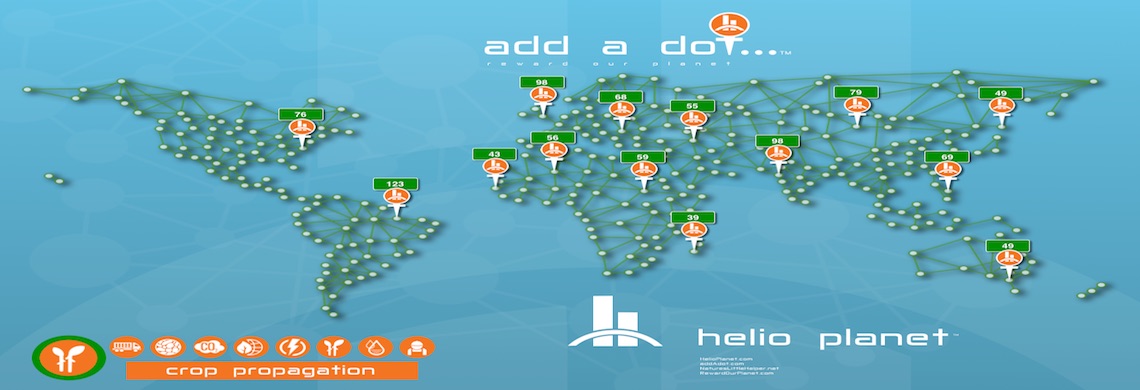

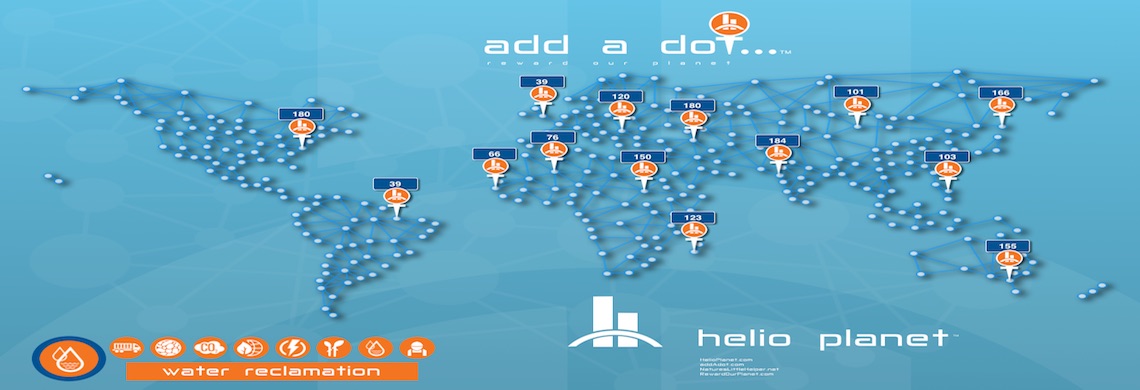

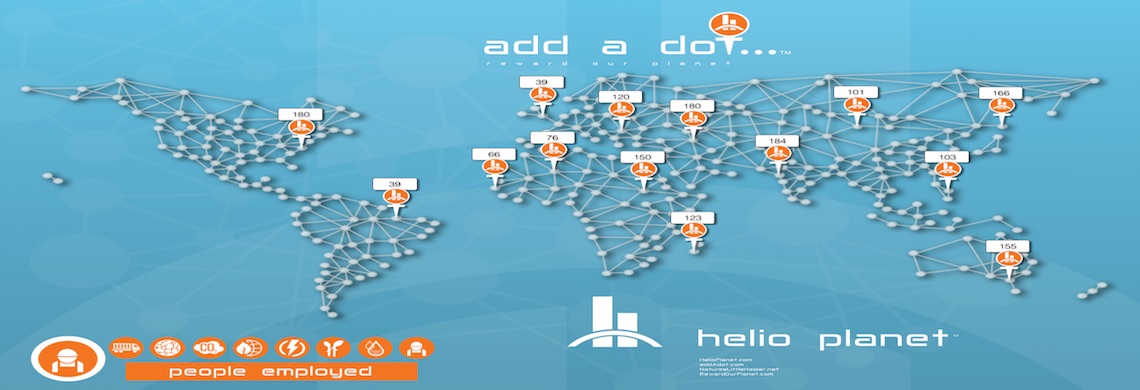

global infographics campaign

add a dot..™

is a global initiative to eradicate harmful waste from our PLANET

each dot we add on the map is a new HRU installation

each HRU is '...nature's little helper'

'another dot...another HRU...less waste'

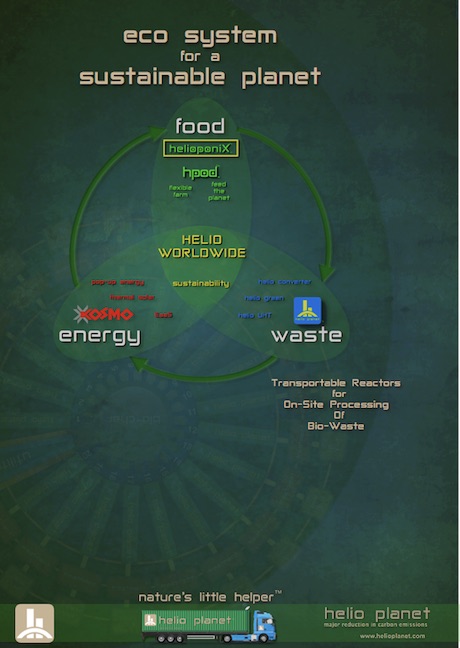

integrated ecosystems

The United Nation Environmental Programme Division (UNEP DTIE IETC) reported in March 2010 that the issue of waste has to be realigned with a new 21st century perspective:

‘…the 20th century waste management focus was based on - how do we get rid of our waste efficiently with minimum damage to public health and the environment?

‘…the 21st century resource management focus is - how do we handle our discarded resources in ways which do not deprive future generations of some, if not all, of our values?’

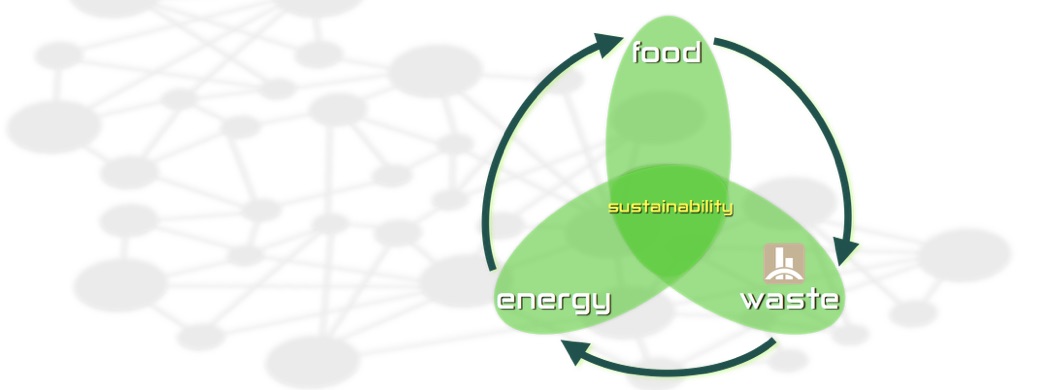

Helio Planet has a major part to play within the ‘Sustainability Eco System’. The three main constituents of the Sustainability Eco System are:

- food

- waste

- energy

Helio Planet’s activities focus on processing our valuable waste resource.

environmental sustainability

Helio Planet has many other possibilities for the HRU plant to be utilised in parallel with other recycling and waste management initiatives:

- Municipal Solid Waste (MSW)

- Meat and Bone Meal (MBM)

- Tyre Recycling and Conversion (TRC)

- Tanneries Sludge Waste (TSW)

- Oil Refinery Sludge (ORS)

- Plastic Waste Disposal (PWD)

- Brick works (BWP)

There is no such thing as 'safe disposal' of sludge. If landfilled, it will contaminate the groundwater. If incinerated, it will cause serious air pollution. When dumped in the ocean, it will cause great harm to marine ecology, and "land application," the latest disposal tactic, may be the most insidiously dangerous of all.

The growth drivers for Helio Planet’s products and services pivot around ‘FOOD’ and ‘ENERGY’. With the steady growth in global population there is a continuously rising demand for both food and energy. Rising energy costs, depletion of energy resources and environmental regulation place Helio Planet's products on centre stage of the global market place.

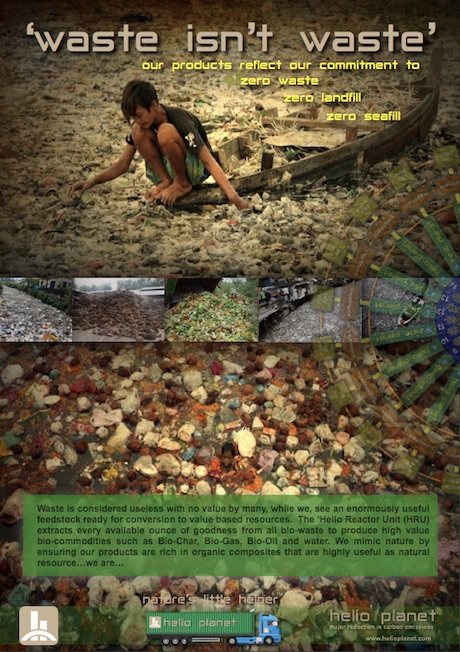

The gruesome reality

With urbanisation growth and higher income levels MSW generation per capita has grown to alarming levels.

Fact 1:On 31 October, 2011, the United Nations organisation (UN) recorded a global population of 7 billion. Since then the UN Population Division projects a world population of 9 billion in 2043 and 10 billion in 2083.Fact 2:

The World Bank Group has concluded in it’s knowledge pages that Municipal Solid Waste (MSW) generation is projected to double every 20 years.Fact 3:

Based on estimates by the Global Footprint Network ‘…on 8 August, 2016, we began to use more from nature than our planet can renew in the whole year. We use more ecological resources and services than nature can regenerate through overfishing, over harvesting forests and emitting more carbon dioxide into the atmosphere than forests can sequester. The world’s population currently consumes the equivalent of 1.6 planets a year’.

In combination these major issues, if left unresolved, will equate to an unsustainable planet.

Here we are today with over 7 billion people on our planet with images of the waste around us!!

Pause for a moment...in 20 years...these type of images will exist in many new locations on our planet!!

Help us with the add a dot...™ campaign to stop this overgrowing global crisis.

'another dot...another HRU...less waste'

resources

brochures

Corporate

The corporate brochures provide an overview of our corporation.

brochures

technology

The technology brochures provide an insight into our various technologies.

brochures

transportable

The transportable brochures provide an overview of the technology, features and benefits.

brochures

bio-char

The bio-char brochures provide features and benefits information.

brochures

scaleability

The scaleability brochures provide capability, features and benefits information.

brochures

platform

The platform brochures provide technology, features and benefits information.

brochures

landscape

The landscape brochures provide information and comparisons of waste disposal methods.

brochures

ecosystems

The ecosystems brochures provide information on the environmental ecosystems.

brochures

waste change

The waste change brochures provide information and impact statements related to global climate and waste changes.

brochures

waste management

The waste management brochures provide insight into process and capabilities.

brochures

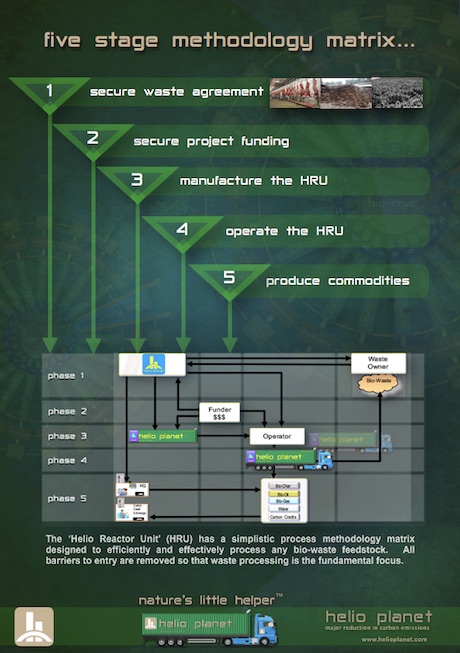

methodology

The methodology brochures provide information on capability and project methods.

brochures

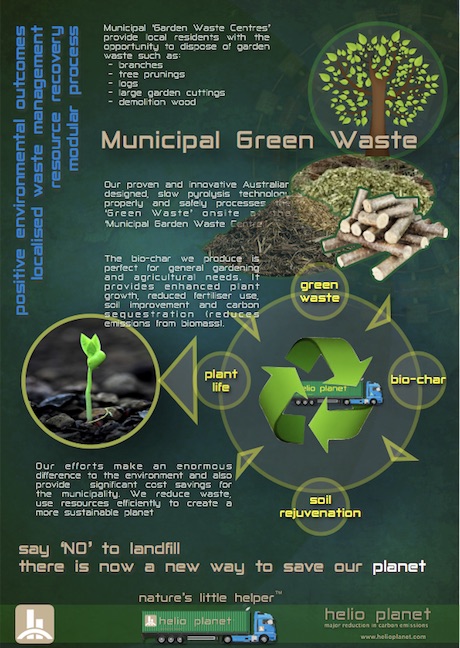

waste specific

The waste specific brochures provide information and capability for various waste feedstock.

globally

every day...every transportable unit...

transportable

tonne of biochar

thousand lt. of water

thousand population coverage