Technology

TECHNOLOGY FEATURES

LTNE Reactor

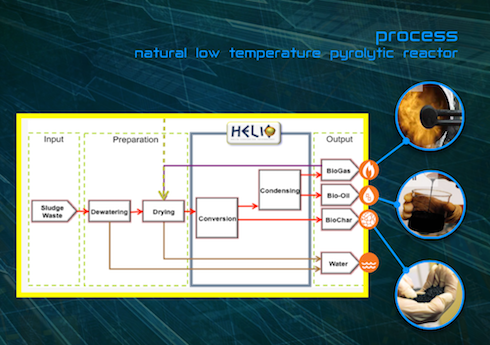

Helio Planet’s technologically advanced transportable Helio Reactor Unit (HRU) with Low Temperature Natural Extraction (LTNE) waste processing innovation redefines the balance between economics and environment sustainability.

The transportable waste processing plant eradicates waste, is sophisticated in operation, creates zero emissions, produces commodities for sale and generates abundant electricity for localised communities. Data collection and battery recharging capabilities are also added to complete the technology platform.

The main pyrolytic conversion chamber is loaded with the pretreated waste input feedstock. During the pretreatment process significant water is extracted to ensure the waste entering the pyrolytic chamber is maintained at about 10% moisture content. This clean condensed water can be sold to third parties as non-potable water that is not for drinking quality but may still be used for many other purposes.

The sealed, oxygen deprived, chamber is heated on the outside to 400°C (800°F), a relatively low temperature compared to other thermal processing plants. With a thirty minute processing cycle, the bio-waste contents on the inside of the chamber remoleculise to commodities of bio-char, bio-gas and bio-oil.

The HRU main features include:

- transportable (to position where the waste is situated)

- modular (to provide unlimited scaleability)

- flexible (to processes a multitude of waste feedstock)

- efficient (to produce significant resource recovery)

- systematic (for no environmental emissions)

- adaptable (to generate energy from waste)

- capable (to reduce operational costs)

- scaleable (to maximise economic returns)

- natural extraction (to retain the 'goodness' in recovered resources)

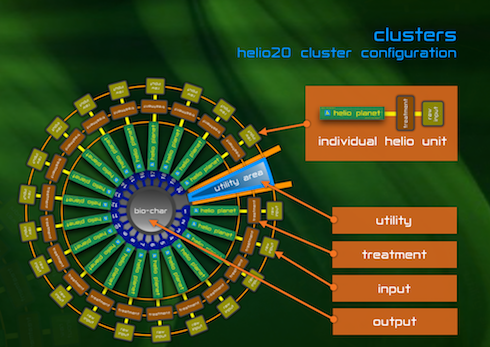

The Helio Reactor Units (HRU) are arranged into compact clusters to process large volumes of waste from local communities or cities. These clusters form efficient waste processing plants capable of multi-volume waste handling. The essence of this configurable cluster is not only the input volume processing capability but its operational runtime efficiency. Any maintenance issues are localised and dealt with quickly and easily. As maintenance issues are localised to each HRU unit the operational uptime of the entire cluster is kept at a maximum. In case of a catastrophic event in a single HRU it is simply totally replaced with a new unit without effecting the continued operation of the cluster. While the faulty unit is replaced the remaining units in the cluster are still performing to maximum capacity without effecting the input processing of the waste volume.

View Portfolio