Design / Process

design / process description

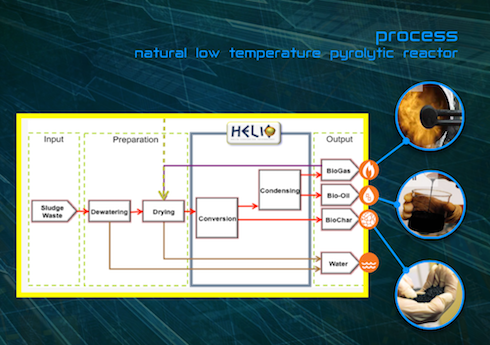

Low Temperature Natural Extraction (LTNE)

The 'Low Temperature Natural Extraction’ (LTNE) technology provides a new revolutionary product for the sludge, municipal solid waste and other waste organics market. Unlike most other processes the technology offers significant resource recovery options.

The LTNE technology has considerable environmental and societal benefits over all ‘classic’ sludge and waste disposal alternatives (including recycling to agriculture, landfill and incineration) and generates ‘renewable’ energy and carbon sequestration credits thereby reducing emissions of greenhouse gases.

The key to the LTNE system is the molecular re-arrangement by heating, achieved by a thermal reactor process, plus intimate contacting of the product streams in the main conversion reactor to obtain the optimum quality of output product. In this process, the waste molecules are heated, to above 400°C (800°F), in an oxygen free environment (no combustion), and re-ordered into Bio-Gas, Bio-Char and Bio-Oil.

Many sources of organic matter can be used as feedstock for the LTNE reactor process. Suitable plant material (green waste, sawdust, waste wood, woody weeds), agricultural sources (nut shells, straw, cotton trash, rice hulls, switch grass), poultry litter, dairy manure and potentially other manures. The LTNE reactor process is used as a form of thermal treatment to reduce waste volumes of domestic refuse. Some industrial by-products are also suitable feedstock including paper sludge and distillers grain.

One of the key strengths of the LTNE technology is its ability to handle pollutants. With sludge containing a number of pollutants such as heavy metals, organochlorines, pathogens, toxins and/or Endocrine Disrupting Compounds (EDC’s). The majority of the heavy metals partition into the Bio-Char and, when this is combusted, the heavy metals become tightly bonded to the resulting ash. Unlike almost all other thermal processes, the heavy metals remain in the solid phase and are neither vapourised nor leachable. All organochlorines, toxins, pathogens and EDC’s are destroyed.

There is a global impact of bio-char on soil ‘Nitrogen Cycling’.

There are now numerous scientific studies that combine biological, geological and chemical facilities as a single biogeochemical unit to discover an ‘Integrated Biological System’. (Glaser et al, 2000)

The pyrolysation of waste to produce bio-char is the fundamental building block of all such activities. This scientific focus has identified four main ares of integration within biological and commercial systems:

- Climate change mitigation

Bio-char’s carbon sequestration properties activates ‘Carbon Negative’ agriculture - Sustainable intensification of agriculture

Amazon Dark Earth (ADE) (the Amazonian Terra Pretta soils) act as the model for present-day agriculture - Bioremediation

Bio-Char’s filtration and microbial habitation properties are utilised to remove toxins from soil - Product research

A multitude of new product innovation is continually emerging

Bio-char is growing in acceptance as a ‘wonder-product’ within the farming and scientific communities. It’s unique porous structure has many beneficial advantages in rejuvenating soil and interaction with fertilisers. Bio-char’s unique structure has many advantages within the agricultural sector. Helio Planet’s processes match product capability, type of input waste feedstock to achieve maximum ‘goodness’ retention from the bio-char.

View Portfolio

![]()

![]()